Genbrugsmaskine til pelletering af PVC-plast

Beskrivelse:

Twin screw extruder PVC plastic pelletizing recycling machine are applied to the waste materials, som kræver høj forarbejdningsydelse af smeltning, volatilisering, filtrering osv., mainly works for the job of PVC scraps recycling and re-pelletizing.

PVC plastic pelletizing machine with international advanced recycling technology and combined with the actual application condition. This PVC plastic pelletizing machine is design specializes for recycling the recycled washed plastic PVC plastic flakes/scraps, such as PVC pipe flakes/scraps, PVC sheet flakes/scraps etc.

Efter forarbejdningsteknikker såsom fodring, opvarmning, smelte, cutting, cooling etc., the final products are PVC plastic pellets/granules that can be to produce new PVC plastic products.

Vidoe of PVC plastic pelletizing recycling machine

Features of PVC plastic pelletizing recycling machine

Skruen er lavet af højt værktøjsstål 38 CrMoALA eller W6Mo5Cr4V2. Speciel skruekombination Euro-stil rektanglet cylinder, reflux kølekanal optimeret og bortskaffet, hvilket gør temperaturforskellen i D-områder mindre.

Innoveret design af varmelegeme-stramte stil sikrer høj effektivitet af varmeoverførsel og høj levetid for varmelegeme.

Materialet er brugt højkvalitets nitridstål, korrosionssikker eller antifriktion med tilsvarende forarbejdede specialdesignede to sæt vakuum.

New-style project of parallel three-axis driving makes the convex axis, convey Chain, decelerate and torque get together, which keep it compact, and the key bearings are imported soakage and spraying lubrication integrate smoothly technics, strengthening of tooth face, so they can ensure high torque, high precision and low noise

Det valgte materiale af drivkomponenter er lækkert, inklusive super intention legering, cementering af stål, cementering og slibning.

Working Flow of PVC plastic pelletizing recycling machine:

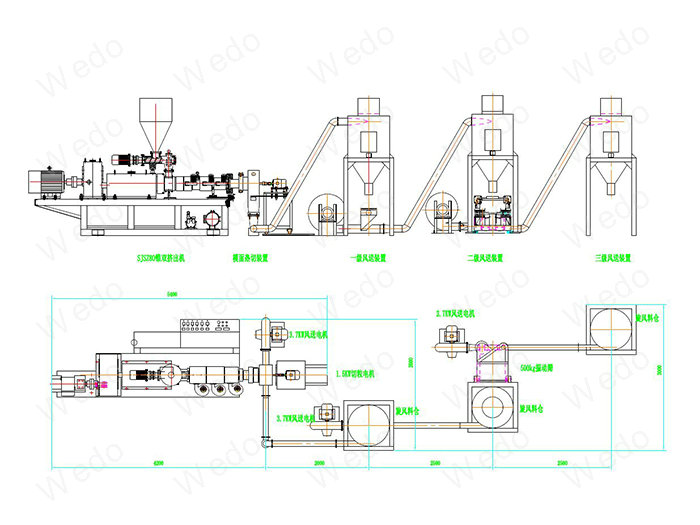

Screw feeder → Efficient extruder → Cutting → Blower → Storage hopper → Blower → Storage hopper → Electric control panel

Working Flow of PVC plastic pelletizing recycling machine:

Photos of PVC plastic pelletizing recycling machine

Overview of PVC plastic pelletizing recycling machine:

Conical Twin Screw Extruder of PVC plastic pelletizing recycling machine:

Cutting die head of PVC plastic pelletizing recycling machine:

Cutting die head view of PVC plastic pelletizing recycling machine:

recycled PVC material of PVC plastic pelletizing recycling machine:

The final product PVC pellets from PVC plastic pelletizing recycling machine:

PVC pellets from PVC plastic pelletizing recycling machine:

Main parts in PVC plastic pelletizing recycling machine

- Skrueføder: det første trin i pelletiseringsgenbrugsmaskinen, Pvc plastic flakes/scraps conveyed into the hopper through screw, skrueforbindelsessensoren for at registrere materialet i tragten, når flagerne er fyldt i tragten, skruen stopper; og en gang tom, skrueføderen begynder at virke.

- Ekstruder: til plastificering og afgasning, en specialiseret enkeltskrueekstruder, der anvendes til at smelte det forkomprimerede materiale. Plastikrester vil godt smelte, plastificeret i første trins ekstruder, og plasten vil blive ekstruderet af anden trins ekstruder. Med dobbelt-zone vakuumafgasningssystem, flygtige stoffer såsom lavmolekylær og fugt vil blive fjernet effektivitet, især velegnet til kraftig trykt film og materiale med et vist vandindhold.

- Skære pelletering: leveres med skæreblade af speedstål og hårdlegeret stål for pålidelig ydeevne. Kompakt struktur giver mindre vedligeholdelse.

4, Blower and hopper: to cooling the PVC pellets and storage the pellets.

Advantage of PVC plastic pelletizing recycling machine:

Meget lav efterspørgsel efter arbejdskraft.

Automatisk konstant temperaturkontrol.

CE-certificering, ISO9001 certificering, SGS certificering

Stabilt løb, højere output og lavere energiforbrug.

Konfiguration baseret på kundekrav og materiale, og give et fornuftigt forslag.

Technical Parameter of PVC plastic pelletizing recycling machine extruder:

| Model | Strøm (kw) |

Screw Diameter (mm) | Screw Qty. | Screw rotation speed(rpm) | Designed Output (kg/t) | Center Height (mm) | Dimension(L*W*H) (mm) |

| 65/132 | 37 | Φ65/132 | 2 | 34.7 | 300 | 1050 | 3715x1520x2450 |

| 80/156 | 55 | Φ80/156 | 2 | 34.7 | 400 | 1050 | 4750x1550x2460 |

| 92/188 | 110 | Φ92/188 | 2 | 34.7 | 750 | 1250 | 6725x1550x2814 |