HDPE PP jäätmete plasthelveste granuleerimismasin

Kirjeldus:

HDPE PP waste plastic flakes pelletizing recycling machine designed with the actual application condition. This HDPE plastic pelletizing machine is specializes for recycling the recycled washed plastic PP HDPE rigid plastic flakes, such as plastic milk bottle flakes, shampoo bottle flakes, medicine bottle flakes, PE drinking bottle flakes, plastic basin flakes, plastic bucket flakes, jne.

After the processing of feeding, küte, sulama, jahutamine, kuivatamine, lõikamine jne., the final products are HDPE plastic pellets/granules that can be to produce plastic chair, plastic profile, plastic bottle, drenaažitorud, plastic sheet etc.

vidoe of HDPE PP waste plastic flakes pelletizing recycling machine

Working Flow of HDPE PP waste plastic flakes pelletizing recycling machine:

Screw feeder → Efficient extruder → Non-stop hydraulic screen filter changer → (second stage extruder → hydraulic screen filter changer → die head →) Water cooling → Strand cutting → Blower → Storage hopper → Electric control panel

Photos of HDPE PP waste plastic flakes pelletizing recycling machine

Mian extruder machine of HDPE PP waste plastic flakes pelletizing recycling machine

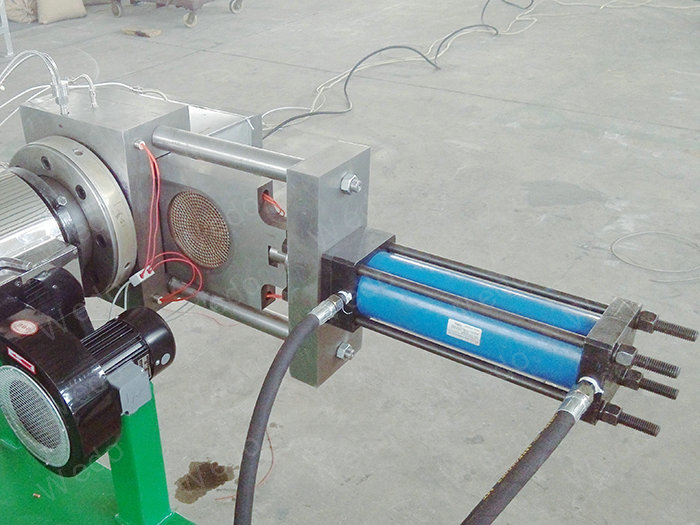

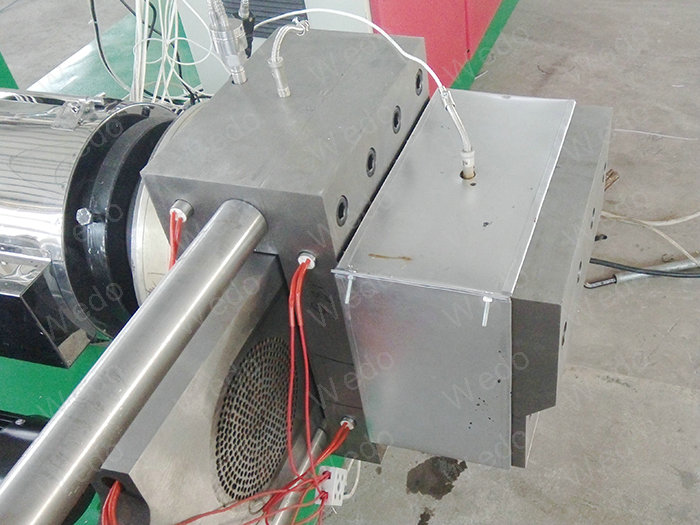

No-stop hydraulic sceen changer of HDPE PP waste plastic flakes pelletizing recycling machine

Second extruder, baby extruder of HDPE PP waste plastic flakes pelletizing recycling machine

hydraulic station of HDPE PP waste plastic flakes pelletizing recycling machine

Die head of HDPE PP waste plastic flakes pelletizing recycling machine

Pelletizer cutter of HDPE PP waste plastic flakes pelletizing recycling machine

Final pellets get from HDPE PP waste plastic flakes pelletizing recycling machine

The main parts function in HDPE PP waste plastic flakes pelletizing recycling machine(canbe customizable)

- Kruvisöötur: granuleerimise ringlussevõtu masina esimene samm, plastic scraps such as PP PE rigid washed flakes conveyed into the hopper through screw, kruviühendusandur punkris oleva materjali tuvastamiseks, kui helbed on punkris täis, kruvi peatub; ja kord tühi, kruvisöötur hakkab tööle.

- Ekstruuder: plastifitseerimiseks ja degaseerimiseks, spetsiaalne ühe kruviga ekstruuder, mida kasutatakse eelnevalt tihendatud materjali sulatamiseks. Plastijäägid sulavad hästi, plastifitseeritakse esimese etapi ekstruuderis, ja plastik ekstrudeeritakse teise etapi ekstruuderiga. Kahetsoonilise vaakumdegaseerimissüsteemiga, lenduvad ained, nagu madalmolekulaarne ja niiskus, eemaldatakse tõhusalt, eriti sobilik rasketele trükitud kiledele ja vähese veesisaldusega materjalidele.

- Non-stop hüdrauliline sõelafiltri vahetaja: kaheastmeline filtreerimine, enne filtreerimist esimeses ekstruuderis, ja peenfiltreerimine teises ekstruuderis, filtreerimissõelte vahetamise sageduse vähendamiseks. Filtritehnoloogiale esitatavad nõuded sõltuvad suuresti nii sisendmaterjali kvaliteedist kui ka graanulite kavandatavast kasutamisest.

- Water cooling: tehtud 304 roostevaba teras, 4 meters length that fill with water, too cooling the melted plastic.

- Lõikamine granuleerimine: supplied with speed steel and hard alloy steel cutting blades for reliable performance. Kompaktne struktuur võimaldab vähem hooldust.

Parameters of HDPE PP waste plastic flakes pelletizing recycling machine:

| VÕIMSUS (kg/h) |

ENERGIATARVE (kw) |

VEETARBIMINE | TÖÖ | NIISKUSI SISU |

| 100-150 | 150 | Hoidke vett jahedas | 1-2 | <2% |

| 250-300 | 200 | Hoidke vett jahedas | 1-2 | <2% |

| 350-400 | 280 | Hoidke vett jahedas | 1-2 | <2% |

| 450-500 | 360 | Hoidke vett jahedas | 1-2 | <2% |

Advantage of HDPE PP waste plastic flakes pelletizing recycling machine:

Väga madal tööjõuvajadus.

Stabiilne jooks.

Automaatne konstantse temperatuuri reguleerimine.

CE sertifikaat, ISO9001 sertifikaat, SGS sertifikaat

Konfiguratsioon vastavalt kliendi nõudmistele ja materjalile, ja andke mõistlik soovitus.