PP PE jäätmete plastkile granuleerimise ringlussevõtu masin

Kirjeldus:

PP PE jäätmete plastkile granuleerimise ringlussevõtu masin, millel on rahvusvaheline täiustatud ringlussevõtu tehnoloogia ja mis on ühendatud tegeliku kasutustingimustega. See plastist granuleeriva ringlussevõtu masina disain on spetsialiseerunud pestud plastist PE-kile ringlussevõtuks, nagu PE-kilekotid, plastist pakkekiled, plastikust ostukotid, põllumajanduskile jne.

Pärast PE PP plastist granuleerimismasina töötlemist, lõpptoodeteks on plastgraanulid/graanulid, mida saab toota kilekotte, drenaažitorud, plastikust tahvel/leht jne.

Video PP PE jäätmete plastkile granuleerimismasinast

Kogu PP PE jäätmete plastkile granuleerimismasinate ringlussevõtu masin sisaldab(kohandatav):

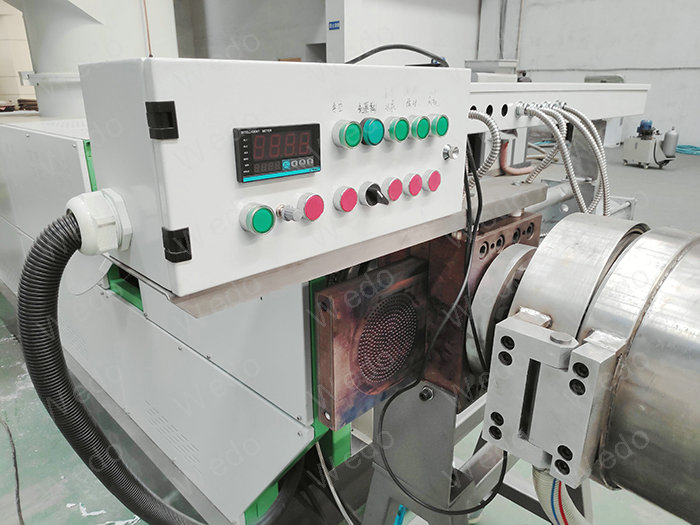

Lintkonveier → Kompressioon (aglomeraator) → Tõhus ekstruuder → Non-stop hüdrauliline sõelafiltri vahetaja → Vesirõnga lõikamine → Vibratsioonimasin → Veetusmasin → Puhur → Hoiupunker. Elektriline juhtpaneel

Fotod PP PE jäätmete plastkile granuleerimismasinast

PP PE jäätmete plastkile granuleerimismasina lintkonveier

Suru tünn, PP PE jäätmete plastkile granuleerimismasina aglomeraator

PP PE jäätmete plastkile granuleerimismasina ekstruuder

PP PE-jäätmete plastkile granuleerimismasina hüdrauliline filtriekraani vahetaja

PP PE jäätmete plastkile granuleerimise ringlussevõtu masina kastmislõikepea

PP PE-jäätmete plastkile granuleerimismasina vibreeriv masin

Graanulid saadakse PP PE jäätmeplastkile granuleerimismasinast

Peamiste osade funktsioon PP PE-jäätmete plastkile granuleerimismasinas:

- Lintkonveieri söötmine: standardse disainina, plastijäägid nagu kile, kott, hõõgniit, raffia kantakse lintkonveieri kaudu tihendustünni; rullide töötlemiseks’ sissekannet, Rulli mahatõstmise seade on valikuline söötmisviis. Konveierilindi ja veoseadme mootorajamid töötavad koos ABB inverteriga. Konveierilindi etteandekiirus ja rulli mahatõmbamine on täisautomaatne, lähtudes tihendaja tünni ruumist. Metallidetektor saab kombineerida lintkonveieriga, ja saab haakuda juhtimissüsteemiga, hoiatada ja süsteemi peatada, juhuks, kui see metall kruvi sisse.

- Kompressioonitünn: materjali purustamine ja tihendamine, tihendaja pöörlevad terad lõikavad sissetulevad jäägid ära. Kiirete pöörlevate labade poolt põhjustatud hõõrdekuumutamine soojendab jääke, ja lase neil kahaneda veidi allapoole nende koondumispunkti. Optimaalselt kujundatud juhtstruktuur tihendab materjali ja suunab selle ekstruuderi kruvisse. Muljub, kuivatab ja tihendab materjali, mis võimaldab kiiret ja stabiilset söötmist tihendajast otse ekstruuderisse.

- Ekstruuder: plastifitseerimiseks ja degaseerimiseks, spetsiaalne ühe kruviga ekstruuder, mida kasutatakse eelnevalt tihendatud materjali sulatamiseks. Plastijäägid sulavad hästi, plastifitseeritakse esimese etapi ekstruuderis, ja plastik ekstrudeeritakse teise etapi ekstruuderiga. Kahetsoonilise vaakumdegaseerimissüsteemiga, lenduvad ained, nagu madalmolekulaarne ja niiskus, eemaldatakse tõhusalt, eriti sobilik rasketele trükitud kiledele ja vähese veesisaldusega materjalidele.

- Non-stop hüdrauliline sõelafiltri vahetaja: kaheastmeline filtreerimine, enne filtreerimist esimeses ekstruuderis, ja peenfiltreerimine teises ekstruuderis, filtreerimissõelte vahetamise sageduse vähendamiseks. Filtritehnoloogiale esitatavad nõuded sõltuvad suuresti nii sisendmaterjali kvaliteedist kui ka graanulite kavandatavast kasutamisest.

- Lõikamine granuleerimine: die-face veerõnga granuleerimissüsteem on Wedo süsteemi standardne granuleerimismeetod. Isereguleeruv granuleerimispea parima granulaadikvaliteedi saavutamiseks, ja järjepidevalt õige terade rõhk tagab pika töötamise. Lõiketerade pöörlemiskiirus on automaatne, mis põhineb sulati väljapressimise rõhul. Täiustatud veetustamise vibratsioonisõel, mis on kombineeritud vertikaalse tsentrifugaalse veetustamisega, pakub suure jõudlusega kuivatatud graanuleid.

PP PE jäätmeplastkile granuleerimismasina parameetrid:

| VÕIMSUS (kg/h) |

ENERGIATARVE (kw) |

VEETARBIMINE | TÖÖ | NIISKUSI SISU |

| 100-150 | 150 | Hoidke vett jahedas | 1-2 | <2% |

| 200-300 | 200 | Hoidke vett jahedas | 1-2 | <2% |

| 300-400 | 280 | Hoidke vett jahedas | 1-2 | <2% |

| 450-500 | 350 | Hoidke vett jahedas | 1-2 | <2% |

| 700-800 | 460 | Hoidke vett jahedas | 1-2 | <2% |

PP PE jäätmete plastkile granuleerimise ringlussevõtu masina eelis:

Väga madal tööjõuvajadus.

Stabiilne jooks.

Automaatne konstantse temperatuuri reguleerimine.

CE sertifikaat, ISO9001 sertifikaat, SGS sertifikaat

Konfiguratsioon vastavalt kliendi nõudmistele ja materjalile, ja andke mõistlik soovitus.