PET-muovihiutaleiden pelletointikierrätyskone

Kuvaus:

PET plastic flakes pelletizing recycling machine are applied to the waste materials, joka vaatii korkeaa sulatuksen käsittelytehoa, haihtuminen, suodatus jne., työskentelee pääasiassa PET-romujen kierrätykseen ja uudelleenpelletointiin.

PET plastic granulator machine with international advanced recycling technology and combined with the actual application condition. This PET plastic granulator machine is design specializes for recycling the recycled washed plastic PET plastic flakes/scraps, kuten Cola muovipullojen hiutaleet/romut, puhdistetut vesipullohiutaleet/romut, PET-levyjen hiutaleet/romut, PET-juomapullojen hiutaleet/romut jne.

After processing techniques such as feeding, heating, melt, cooling, drying, cutting etc., the final products are PET plastic pellets/granules that can be to produce new PET plastic products.

Video of PET plastic flakes pelletizing recycling machine

Features of PET plastic flakes pelletizing recycling machine:

The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2. Special screw combination Euro-style rectangle barrel, reflux refrigeration channel optimized and disposed, which makes temperature difference in D areas smaller. Co-rotating Twin Screw Extruder with High Torque Gearbox. Due to high torque gearbox, The specific torque of gearbox is 10.3 N.m/cm3, So we can process PET in lower temp & lower speed, but high output.

Innovated design of heater-tightened style insures high efficiency of heat transfer and high longevity of heater.

The material is used high quality nitride steel, corrosion proof or antifriction with corresponding processed special designed two sets of vacuum. The vacuum system is used for removing moisture & volatile matter from PET. It is assembled with vacuum pumps & collecting tank. With PLC and HMI control for interlock, you will get the vacuum level less than 0.3Kpa. It is very close to the ultimate vacuum. You will get PET with IV drop less than 5%, it is about 0.05dl/g.

The selected material of drive components is dainty, including super intention alloy, cementiteing steel, cementiting and grinding.

Uusi Under Water Strand -pelletointikonejärjestelmä: Nauha menee vesivirran mukana pelletointilaitteeseen, jopa säie katkeaa suodattimen vaihdon aikana, käynnistyksen jälkeen ei tule hukkaa.

Voimme kontrolloida lopullisten pellettien lämpötilaa. Voimme tehdä sen kuumaksi, jos haluat kiteyttää lopullisen pelletin. Se säästää energiaa pellettien lämmittämiseen.

Photos of PET plastic flakes pelletizing recycling machine

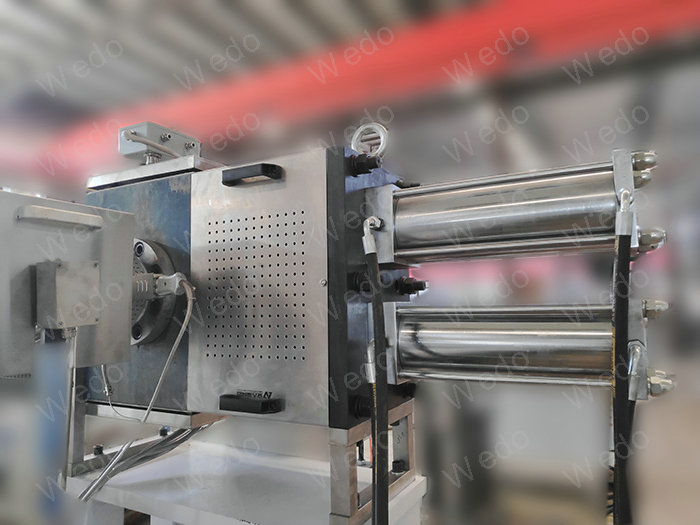

Main extruder, parrallel twin exturder of PET plastic flakes pelletizing recycling machine

Roots vacuum pump of PET plastic flakes pelletizing recycling machine

Hydraulic screen changer of PET plastic flakes pelletizing recycling machine

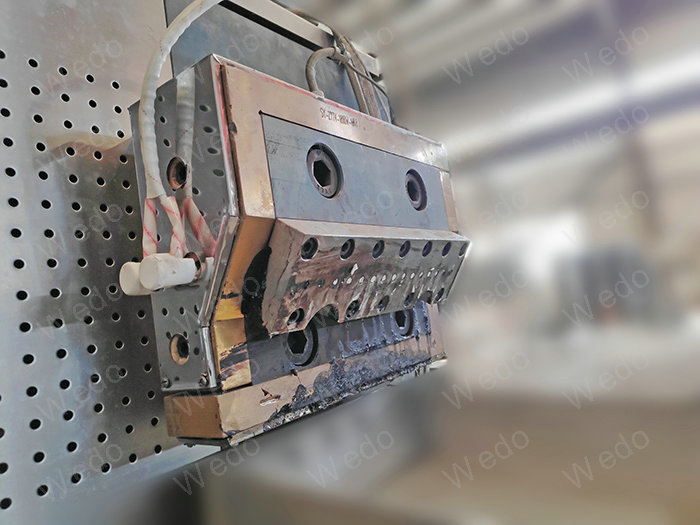

Die head of PET plastic flakes pelletizing recycling machine

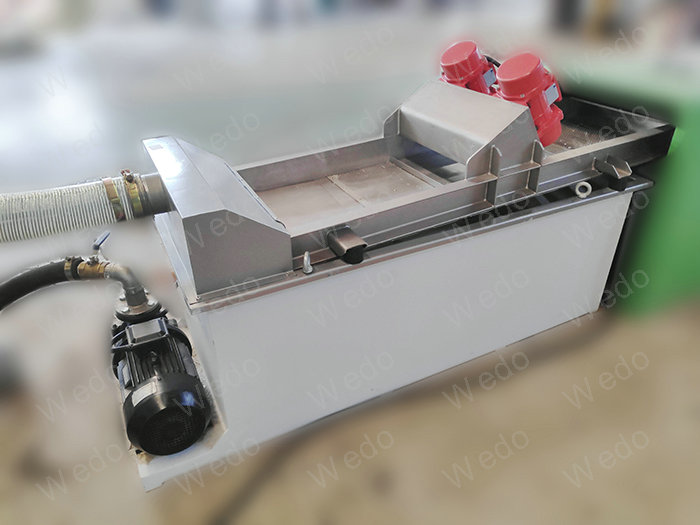

With water cutting, Pelletizer cutter of PET plastic flakes pelletizing recycling machine

Vibrationg machine of PET plastic flakes pelletizing recycling machine

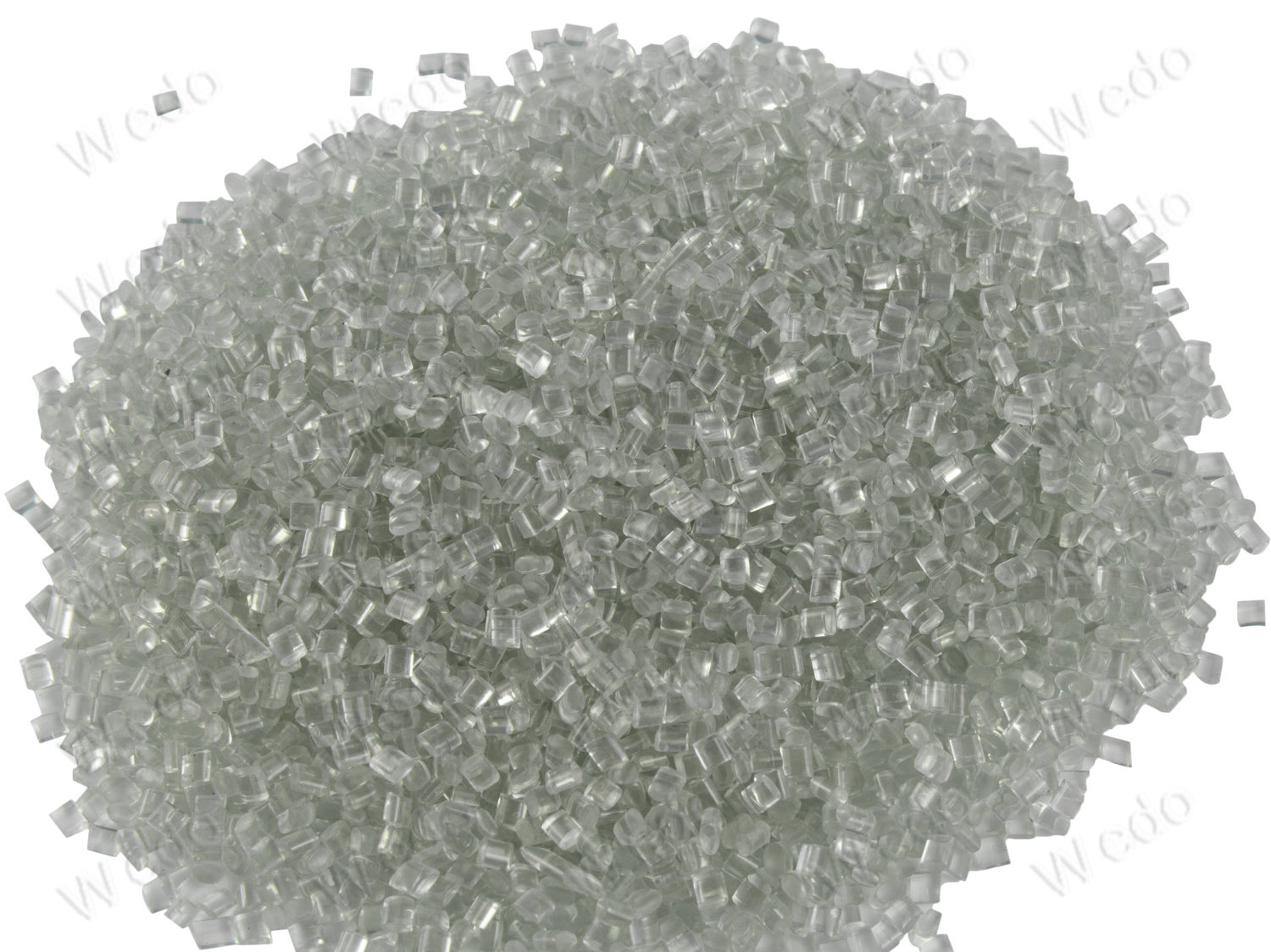

PET pellets get from PET plastic flakes pelletizing recycling machine

Working Flow of PET plastic flakes pelletizing recycling machine:

Feeder → Efficient Extruder → Non-Stop Hydraulic Screen Filter Changer → Water Flow Cooling → Under Waster Cutting → Vibrating → Blower → Storage Hopper → Electric Control Panel

Main parts fuction in PET plastic flakes pelletizing recycling machine

- Screw feeder: the first step of the pelletizing recycling machine, PET plastic flakes/scraps conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

- Extruder: to plasticization and degassing, a specialized single screw extruder applied to melt the pre-compacted material. The plastic scraps will well melted, plasticized in the first stage extruder, and the plastic will be extrude by the second stage extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

- Non-stop hydraulic screen filter changer: double stage filtering, fore filtering in the first extruder, and fine filtering in the second extruder, to reduce the frequency of filtering sieves changing. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

- Water flow cooling: made of 304 ruostumaton teräs, 3 meters length that with flowing water, too cooling the melted PET strand.

- Cutting pelletizing: Water proof design, that can cutting the PET strand in water directly, this can save more waste. Supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

Parameters of PET plastic flakes pelletizing recycling machine:

| CAPACITY (kg/h) |

POWER CONSUMPTION (kw) |

WATER CONSUMPTION | LABOUR | HUMIDITY CONTENT |

| 100-150 | 150 | Keep water cool | 1-2 | <2% |

| 250-300 | 200 | Keep water cool | 1-2 | <2% |

| 350-400 | 280 | Keep water cool | 1-2 | <2% |

| 450-500 | 360 | Keep water cool | 1-2 | <2% |

Advantage of PET plastic flakes pelletizing recycling machine:

Very low labor request.

Automatic constant temperature control.

CE certification, ISO9001 certification, SGS certification

Stable running, higher output and lower energy consumption.

Configuration based on client requirement and material, and give reasonable suggest.