PVC műanyag pelletizáló újrahasznosító gép

Leírás:

Twin screw extruder PVC plastic pelletizing recycling machine are applied to the waste materials, amelyhez az olvasztás nagy feldolgozási teljesítménye szükséges, elpárologtatás, szűrés stb., mainly works for the job of PVC scraps recycling and re-pelletizing.

PVC plastic pelletizing machine with international advanced recycling technology and combined with the actual application condition. This PVC plastic pelletizing machine is design specializes for recycling the recycled washed plastic PVC plastic flakes/scraps, such as PVC pipe flakes/scraps, PVC sheet flakes/scraps etc.

After processing techniques such as feeding, heating, melt, cutting, cooling etc., the final products are PVC plastic pellets/granules that can be to produce new PVC plastic products.

Vidoe of PVC plastic pelletizing recycling machine

Features of PVC plastic pelletizing recycling machine

The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2. Special screw combination Euro-style rectangle barrel, reflux refrigeration channel optimized and disposed, which makes temperature difference in D areas smaller.

Innovated design of heater-tightened style insures high efficiency of heat transfer and high longevity of heater.

The material is used high quality nitride steel, corrosion proof or antifriction with corresponding processed special designed two sets of vacuum.

New-style project of parallel three-axis driving makes the convex axis, convey Chain, decelerate and torque get together, which keep it compact, and the key bearings are imported soakage and spraying lubrication integrate smoothly technics, strengthening of tooth face, so they can ensure high torque, high precision and low noise

The selected material of drive components is dainty, including super intention alloy, cementiteing steel, cementiting and grinding.

Working Flow of PVC plastic pelletizing recycling machine:

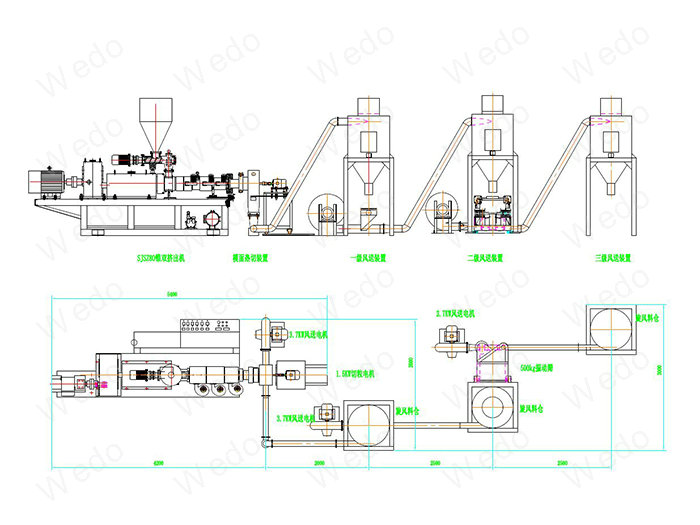

Screw feeder → Efficient extruder → Cutting → Blower → Storage hopper → Blower → Storage hopper → Electric control panel

Working Flow of PVC plastic pelletizing recycling machine:

Photos of PVC plastic pelletizing recycling machine

Overview of PVC plastic pelletizing recycling machine:

Conical Twin Screw Extruder of PVC plastic pelletizing recycling machine:

Cutting die head of PVC plastic pelletizing recycling machine:

Cutting die head view of PVC plastic pelletizing recycling machine:

recycled PVC material of PVC plastic pelletizing recycling machine:

The final product PVC pellets from PVC plastic pelletizing recycling machine:

PVC pellets from PVC plastic pelletizing recycling machine:

Main parts in PVC plastic pelletizing recycling machine

- Screw feeder: the first step of the pelletizing recycling machine, Pvc plastic flakes/scraps conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

- Extruder: a lágyításhoz és a gáztalanításhoz, speciális egycsigás extruder, amelyet az előre tömörített anyag olvasztására alkalmaznak. A műanyag törmelék jól megolvad, az első fokozatú extruderben lágyítják, és a műanyagot a második fokozatú extruder extrudálja. Kétzónás vákuumgáztalanító rendszerrel, Az illékony anyagok, például az alacsony molekulatömegű és a nedvesség hatékonyan eltávolíthatók, különösen alkalmas nehéz nyomott fóliákhoz és némi víztartalmú anyagokhoz.

- Pelletizálás vágása: supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

4, Blower and hopper: to cooling the PVC pellets and storage the pellets.

Advantage of PVC plastic pelletizing recycling machine:

Nagyon alacsony munkaerőigény.

Automatikus állandó hőmérséklet szabályozás.

CE minősítés, ISO9001 tanúsítás, SGS minősítés

Stabil futás, higher output and lower energy consumption.

Konfiguráció az ügyfél igénye és anyaga alapján, és adjon ésszerű javaslatot.

Technical Parameter of PVC plastic pelletizing recycling machine extruder:

| Modell | Power (kw) |

Screw Diameter (mm) | Screw Qty. | Screw rotation speed(rpm) | Designed Output (kg/h) | Center Height (mm) | Dimension(L*W*H) (mm) |

| 65/132 | 37 | Φ65/132 | 2 | 34.7 | 300 | 1050 | 3715x1520x2450 |

| 80/156 | 55 | Φ80/156 | 2 | 34.7 | 400 | 1050 | 4750x1550x2460 |

| 92/188 | 110 | Φ92/188 | 2 | 34.7 | 750 | 1250 | 6725x1550x2814 |