PVC vamzdžių gamybos mašina, PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina

Description PVC pipe making machine:

This set is composed of conical twin-screw extrude, vacuum calibration tank, haul-off machine, cutter, stacker etc. The screw extruder and traction machine adopt imported AC frequency control device. The vacuum pump and traction motor both adopt advanced products. The haul-off machine has many models, such as two-claw, three-claw, four-claw, six-claw etc. It may choose visual blade or cutting type.The unit is of reliable performance and high production efficiency.

At present, in China the plastic pipe production capacity of 3 million tons, mainly PVC, PE and PP-R pipeline three categories, of which PVC pipe market share is the largest plastic pipe, plastic pipe accounted for nearly 70% of the share.

Video of PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina, PVC pipe production line

Process of PVC pipe making machine, PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina

Production Process Raw Material + Additive Preparation → Mixing → Feeding → Conical Twin Screw Extruder → Extrusion Mold → Vacuum Forming Tank → Crawler Haul-Off → Lifting Cutter → Stacker → Completed Product Inspection & Pakuotė

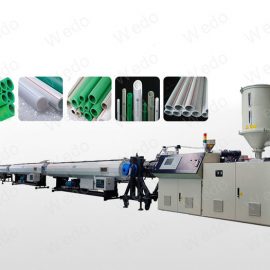

Photos of PVC pipe making machine, PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina

Extruder and vacuum tank pipe making machine, PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina

Haul-off machina and cutting machine of pipe making machine, PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina

Haul-off machina of pipe making machine, PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina

cutting machine of pipe making machine, PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina

Specification PVC pipe making machine, PVC vamzdžių gamybos mašina, PVC vamzdžių ekstruzijos mašina:

| Diameter

(mm) |

16-40

Two Cavities |

20-63

Two Cavities |

20-63 | 50-160 | 63-200 | 160-315 | 315-630 |

| Models | SJZ

51/105 |

SJZ

65/132 |

SJZ

51/105 |

SJZ

65/132 |

SJZ

65/132 |

SJZ

80/156 |

SJZ

92/188 |

| Motor Power | 18.5AC | 37AC | 18.5AC | 37AC | 37AC | 55AC | 110DC |

| Max. Linear Speed | 10 | 15 | 15 | 8 | 3.5 | 3 | 1.2 |

| Max. Išvestis | 120 | 250 | 120 | 250 | 250 | 350 | 800 |