Plastikinė vienos / dvigubos sienos gofruotų vamzdžių išspaudimo gamybos mašina

Description plastic corrugated pipe making machine:

In order to meet the demand of plastic pipe market, Wedo machinery designed and developed this Plastic Corrugated Pipe making machine by absorbing advanced technology from foreign countries plastic machinery industry.

This plastic corrugated pipe extrusion machine is the latest study achievement in the plastic in the plastic extrusion field. This extrusion line is suitable for the high speed extrusion of PP PE PVC material. PP PE PVC plastic corrugated pipe making machine adopts one single or conical twin screw extruder directly extruding and forming technology, human-machine interface control system. It makes high automation degree, reliable quality and stable production become true. And this Corrugated Pipe production line wins our home and abroad customers’ good reputation.

Vidoe of Plastikinė vienos / dvigubos sienos gofruotų vamzdžių išspaudimo gamybos mašina

The consist of Plastikinė vienos / dvigubos sienos gofruotų vamzdžių išspaudimo gamybos mašina

Ekstruderis: Can equipped with fixed-quantity feeding system, High speed and efficiency single screw or conical twin screw extruder is specially designed for extruding PP PE PVC material, automatic temperature control system, vacuum exhaust system and automatic speed control system. This structure assures accurate controlling for the material temperature, plasticization stability and greatly improving corrugated pipe quality.

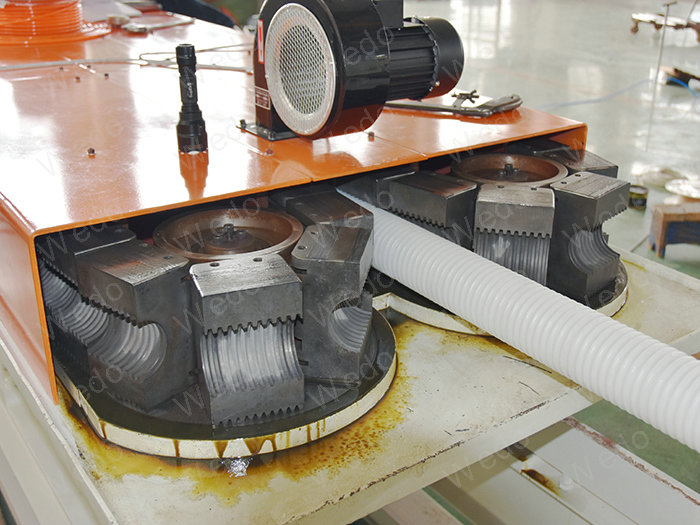

Corrugator: High performance vertical/shuttle corrugator ensure the pipe of good quality and high efficiency Horizontal structure; Chain type transmission; Equipped with open water cooling system. This kind of design greatly increases the production speed. With special and accurate forming module; Cooling air and water system which guarantee the production speed fast. It greatly increases the production speed. Mold moving adopts advanced synchronous upper and lower mechanical drive system. It assures moving accuracy and plastic pipe quality stability. Advanced self-lubricating system makes the forming molds and mold plates abrasions minimize and greatly extend the service life.

Die head: Spiral type; Special structure design; Small volume and clean flow. It is composite die head and made of 40Cr, plating chrome and polishing. which make the corrugated pipe inner and outer layer wall thickness even and forming stability.

Cutting machine: automatically cutting, Effective cutting, high speed, low noise and dustless cutting and so on many advantages.

Control system: high automation, reliable running, lengvas veikimas, remote communication function which can realize remote fault diagnosis and rule out the possibility.

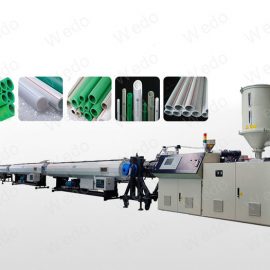

Photos of Plastic single/ double wall corrugated pipe extusion production machine

extruder of Plastic single/ double wall corrugated pipe extusion production machine

die head and the forming machine of Plastic single/ double wall corrugated pipe extusion production machine

forming mold of Plastic single/ double wall corrugated pipe extusion production machine

double wall corrugated pipe produced by double wall corrugated pipe extusion production machine