PET fako tavoahangy plastika misotro tavoahangy milina fanasan-damba fanodinana

Description:

This plastic recycling machine is to crushing washing recycling the waste plastic PET bottles. This PET plastic recycling machine is consist of label remover, sortor, fanorotoro, cold washer, hot washer, dewatering, fonosana rafitra. It can get the clean PET flakes from PE PP cap, oil, PVC label, then use the PET flakes again, to avoid plastic pollution.

This PET plastic recycling machine can easily wash and recycle waste PET bottles. Waste and dirty PET bottles can be disposal step by step in this PET plastic recycling machine. It is special for recycling PET bottles. We equiped drying system at the end of the washing line so that completely dry flakes can be collected and packed directly after been washed.

The whole PET plastic recycling machine can designed based on how dirty the PET bottles are, and make sure of the quality of the final products.

Coordinating the production line with follow processing work (PET pelletizing machine), and it will make waste and dirty PET bottles to be the PET pellets material, and can to producing new PET bottles.

Video of the

PET fako tavoahangy plastika misotro tavoahangy milina fanasan-damba fanodinana:

The whole PET waste plastic drink bottle crushing washing recycling machine line includes(Customizable):

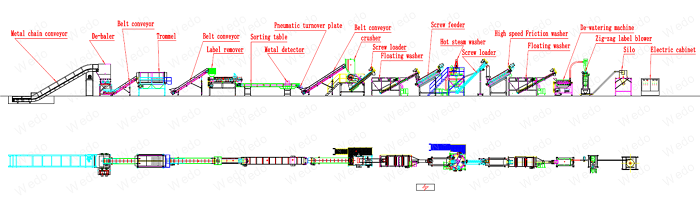

Metal Chain Convery→De-Baler(Baler Opener) →Belt Conveyor→Tromel→Belt Conveyor→Label Remover→Sorting Table→Metal Detactor→Belt Conveyor→Crusher→Screw Loader→Floating Washer→Friction Waser→Hot Washer→Screw Loader→Friction Washer→Floating Washer→Dewatering Machine→Zig-Zag Separater→Silo

layout of PET waste plastic drink bottle crushing washing recycling machine

The fuction of some main parts:

- Belt Conveyor: The materials go into the crusher by the crawler belt, which is move by inside scroll wheel.

- Label Remover: Remove the label from the bottles.

- Manual Sorting Belt: If the label still in the bottle, worker can remove the label by hand. In addition, can separate the different color by hand.

- Mpanorotoro / Grinder: Crushing the material into small size.

- Screw Loader: to transform the material to next step.

- Hot Washer: To washing off the dirty, like oil, sand, in hot washer need use the detergent, then can get very clean PET flakes.

- High-speed Friction Washer: Through the high speed on the shaft of the vane flap and spray water to the common function of good cleaning effect.

- Fanasan-damba mitsingevana: It used in cleaning pet flakes, make the flakes cleaner and whiter. Also is the necessary equipment of the bottle and bottle cap.

- Fanalana rano: Esory ny rano avy amin'ny flakes, ny hamandoana afa-po dia latsaky ny 2%.

Photos of the

PET fako tavoahangy plastika misotro tavoahangy milina fanasan-damba fanodinana

Chain coveyor of PET waste plastic drink bottle crushing washing recycling machine

De-baler machine of PET waste plastic drink bottle crushing washing recycling machine

Trommel of PET waste plastic drink bottle crushing washing recycling machine

De-labeling, label remover machine of PET waste plastic drink bottle crushing washing recycling machine

Granulator, crusher machine of PET waste plastic drink bottle crushing washing recycling machine

De-watering machine, centrifuge dryer machine of PET waste plastic drink bottle crushing washing recycling machine

Technical data

| Input capacity | 1000kg/h | 1500 kg/h | 2000 kg/h |

| Workshop(M*M*M) | 60 (L)×10(W)×6(H) | 70(L)×10(W)×6(H) | 90(L)×18(W)×6(H) |

| Labor | 8Persons | 10 Persons | 14 Persons |

| Installation power | 240KW | 307KW | 420KW |

| Water needed: | 4~5Ton/h | 6~8Ton/h | 8~10 Ton/h |

| Final flakes | hamandoana: max 1.5%

Bulk density: 0.3G/CM3 Particle size: 10-16MG Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

hamandoana: max 1.5%

Bulk density: 0.3G/CM3 Particle size: 10-16MG Metal content: max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

hamandoana: max 1.5%

Bulk density: 0.3G/CM3 Particle size: 10-16MG Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

After this PET plastic recycling machine line, we also supply the following production lines of PET plastic pelletizing machine, that to make the PET flake become the PET pellets.