Plastic granulator, crusher, grinder machine

Description:

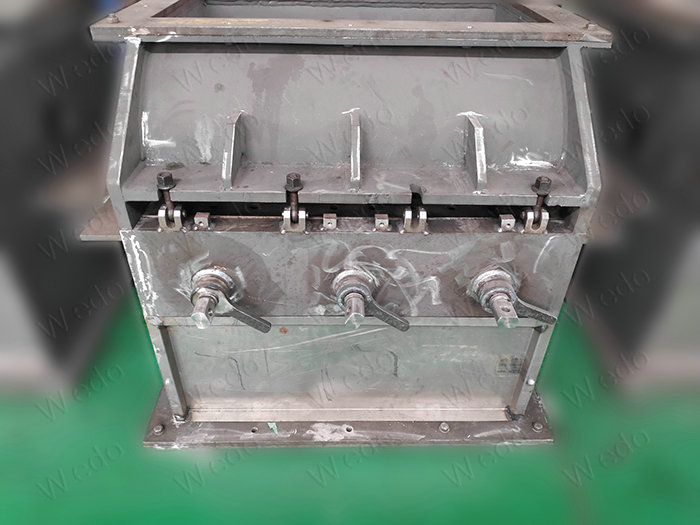

Plastic Granulator, or sometimes called Crusher/Grinder, has the unique ability, can quickly and efficiently cut the plastic scrap into small uniform flakes or regrinds for recycling. At the core the grinder is an open rotor mount with heavy-duty knives in v-shape array. As the rotor is spun at high speeds, the rotor knives come in contact with stationary knives that are mounted within the cutting chamber. The material is continuously cut until they are small enough to pass through a screen mesh holes.

Granulator-rotor we have 10 rotor and 4 stationary knives or 6 rotor and 4 stationary knives. All knives use only high quality D2 (equivalent to SDK11) high-carbon, high-chromium steel which ensures longest usage times before requiring sharpening. All knives are easily adjustable with hydraulic assisted access to the cutting chamber. Depending on your application, we provides both dry and wet grinder.

Video of Plastic granulator, crusher, grinder machine:

Characteristics of Plastic granulator, crusher, grinder machine:

- Plastic Granulator(Crusher/Grinder) based on advantages of the PC series was developed into an economical Granulator(Crusher/Grinder), although without insulation sound cabinet and it appearance is more perfect,

- Our new design of the Grinder(Crusher/Granulator), it is easy for change the knifes (blades). The knife can change front or back.

- Granulator(Crusher/Grinder)is widely applicable to grinding variety of solid waste products, such as injection parts, waste plastic films, sheet, bottles, electric wire, cables, woven bags etc. it can be granulating high quality and uniform granules.

- Easy to operate, low electricity consumption & durable and low noise.

- Uses high quality steel material especially for making cutter of the crushers.

- Blades base is made of high quality steel, hard to be broken and damaged; Blades base structure is stable and durable

- Easy to clean and maintain: The hopper, crusher room, blades and screen can be removed and mounted easily.

- Less occupied area.

- We can also according Client requirement to produce.

- Suitable for recycling PVC PE HDPE LDPE PP and other plastics.

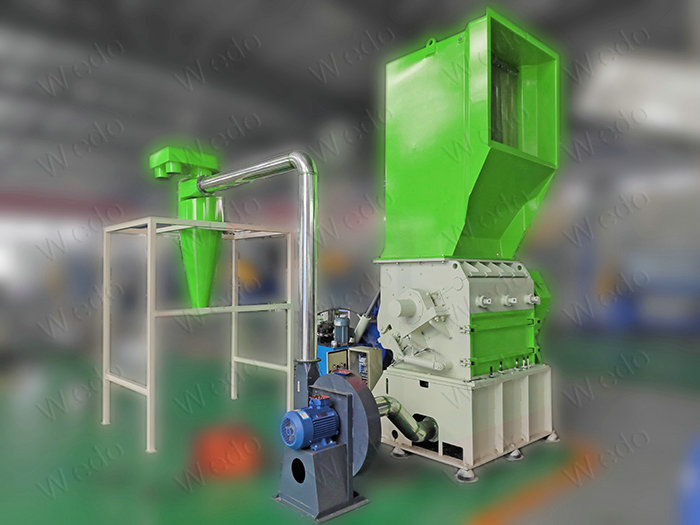

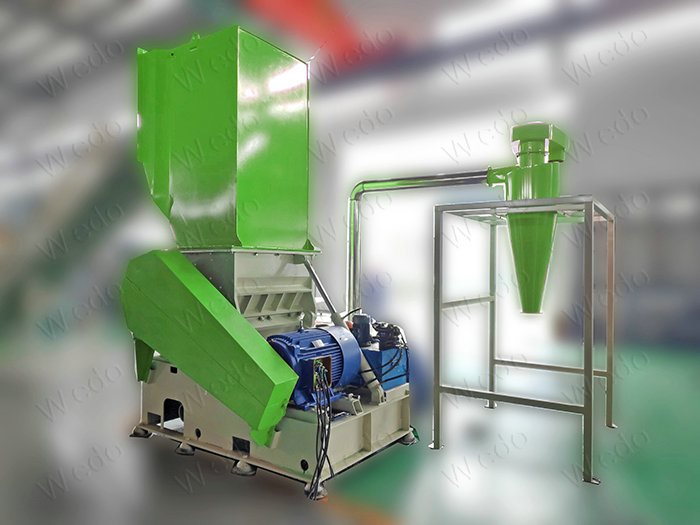

Photos of the Plastic granulator, crusher, grinder machine:

Over view of the Plastic granulator, crusher, grinder machine:

Plastic granulator, crusher, grinder machine with blower and silo

Plastic granulator, crusher, grinder machine with chamber open

Plastic granulator, crusher, grinder machine crushing chamber

Plastic granulator, crusher, grinder machine crushing chamber before paiting

Crushing shaft and blade of Plastic granulator, crusher, grinder machine

More introduction of the Plastic granulator, crusher, grinder machine:

- The machine is fitted with a special hopper and can be loaded manually or by conveyor belt. This hopper can be adapted to suit individual requirements and ensures a continuous and efficient supply of the material being processed, without any need for manual assistance.

2. The Grinder is of extremely robust construction, and the rotor is driven by a belt drive configuration. On top of the Crusher is a feeding hopper which can be opened hydraulically. The hopper opening is also fitted with curtains to protect the materials from splashing out during operation.

3. The machine is equipped with a quick-change screen, which can opened extremely quickly via a hydraulic system; this helps to gain easy access to the rotor and cutting profile and grinding room, in order to save maintenance and operating cost.

4. The screen perforation is 14mm. This determines the final size of the finished products. The grinder is a fast running machine to reduce the materials to a defined granulates.

Technical Parameters of Plastic granulator, crusher, grinder machine:

| Model | 400 | 600 | 800 | 1000 |

| Diameter of rotating blade (mm) | 250 | 380 | 400 | 650 |

| Quantity of rotating blade | 12 | 18 | 24 | 24 |

| Speed of rotating blade (mm) | 560 | 560 | 560 | 560 |

| Quantity of fixed blade | 2 | 4 | 4 | 4 |

| Diameter of screening sieve hole (mm) | Φ10-14 | Φ10-14 | Φ10-14 | Φ10-14 |

| Capacity (kg/h) | 80-100 | 250-350 | 400-500 | 700-800 |

| Power (kw) | 7.5 | 18.5 | 37 | 55 |

| Size of the feeding inlet (mm) | 260×400 | 400×600 | 420×800 | 600×1000 |

| Weight(kg) | 650 | 1200 | 1500 | 2000 |