Máquina de reciclagem de pelotização de resíduos de filme plástico PP PE

Descrição:

PP PE waste plastic film pelletizing recycling machine with international advanced recycling technology and combined with the actual application condition. Esta máquina de reciclagem de pelotização de plástico é um projeto especializado para reciclar o filme PE de plástico lavado, como sacos de plástico PE, filmes de embalagem de plástico, sacolas plásticas de compras, agricultural film etc.

After PE PP plastic pelletizing machine processing, the final products are plastic pellets/granules, which can be to produce plastic bags, drainage pipes, plastic board/sheet etc.

Video of PP PE waste plastic film pelletizing recycling machine

The whole PP PE waste plastic film pelletizing recycling machine line includes(Customizável):

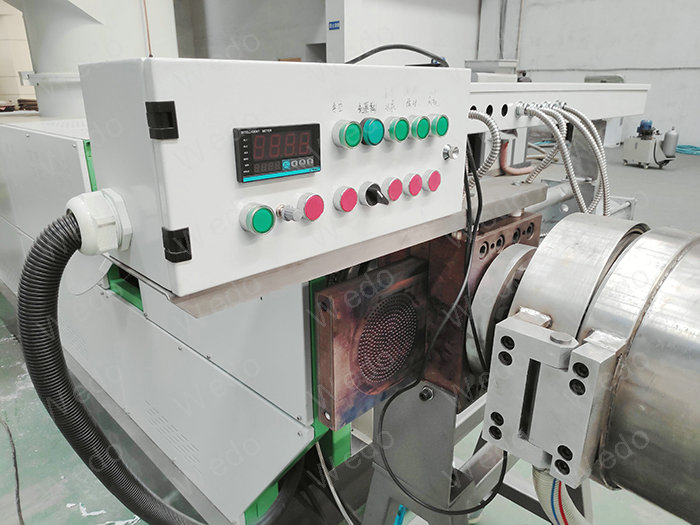

Belt conveyor → Compression barrel (agglomerator) → Efficient extruder → Non-stop hydraulic screen filter changer → Water ring cutting → Vibration machine → Dewatering machine → Blower → Storage hopper. Electric control panel

Photos of PP PE waste plastic film pelletizing recycling machine

Belt conveyor of PP PE waste plastic film pelletizing recycling machine

Compress barrel, agglomerator of PP PE waste plastic film pelletizing recycling machine

Extruder of PP PE waste plastic film pelletizing recycling machine

Hydraulic filter screen changer of PP PE waste plastic film pelletizing recycling machine

Watering cutting die head of PP PE waste plastic film pelletizing recycling machine

Vibrating machine of PP PE waste plastic film pelletizing recycling machine

The pellets get from PP PE waste plastic film pelletizing recycling machine

Function of the main parts in PP PE waste plastic film pelletizing recycling machine:

- Belt conveyor feeding: as standard design, plastic scraps such as film, bag, filament, raffia conveyed into the compacting barrel through belt conveyor; to process rolls’ scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt and roll hauling off is fully automatic based on compactor’s barrel’ space. Metal detector can combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal into the screw.

- Compression barrel: crushing and compacting the material, the rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high-speed rotatory blades will heat the scraps, and let them shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material, which enables a fast and stable feeding from the compactor directly into the extruder.

- Extrusora: para plastificação e desgaseificação, uma extrusora de parafuso único especializada aplicada para derreter o material pré-compactado. As sobras de plástico derreterão bem, plastificado na extrusora de primeiro estágio, e o plástico será extrusado pela extrusora de segundo estágio. Com sistema de desgaseificação a vácuo de zona dupla, voláteis como baixo peso molecular e umidade serão removidos com eficiência, especialmente adequado para filmes impressos pesados e materiais com algum teor de água.

- Non-stop hydraulic screen filter changer: double stage filtering, fore filtering in the first extruder, and fine filtering in the second extruder, to reduce the frequency of filtering sieves changing. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

- Pelotização de corte: die-face water ring pelletizing system as the standard granulating method in Wedo system. Self-adjusting pelletizing head for the best granulate quality, and consistently correct blades pressure can ensure long running. Rotate speed of cutting blades is automatic based on melt extruding pressure. Advanced dewatering vibration sieve combining with vertical-type centrifugal dewatering present high performance dried pellets.

Parameters of PP PE waste plastic film pelletizing recycling machine:

| CAPACITY (kg / h) |

POWER CONSUMPTION (kw) |

WATER CONSUMPTION | LABOUR | HUMIDITY CONTENT |

| 100-150 | 150 | Keep water cool | 1-2 | <2% |

| 200-300 | 200 | Keep water cool | 1-2 | <2% |

| 300-400 | 280 | Keep water cool | 1-2 | <2% |

| 450-500 | 350 | Keep water cool | 1-2 | <2% |

| 700-800 | 460 | Keep water cool | 1-2 | <2% |

Advantage of PP PE waste plastic film pelletizing recycling machine:

Solicitação de mão de obra muito baixa.

Funcionamento estável.

Controle automático de temperatura constante.

Certificação CE, Certificação ISO9001, Certificação SGS

Configuração baseada na necessidade e material do cliente, e dar sugestões razoáveis.