Recyklačný stroj na granulovanie PET plastových vločiek

Popis:

PET plastic flakes pelletizing recycling machine are applied to the waste materials, ktorý vyžaduje vysoký spracovateľský výkon tavenia, volatilizácia, filtrovanie atď., mainly works for the job of PET scraps recycling and re-pelletizing.

PET plastic granulator machine with international advanced recycling technology and combined with the actual application condition. This PET plastic granulator machine is design specializes for recycling the recycled washed plastic PET plastic flakes/scraps, ako sú vločky/odrezky z plastovej fľaše od Coly, vločky/odrezky z fľaše s čistenou vodou, Vločky/odrezky PET fólie, Vločky/odrezky z PET fliaš na pitie atď.

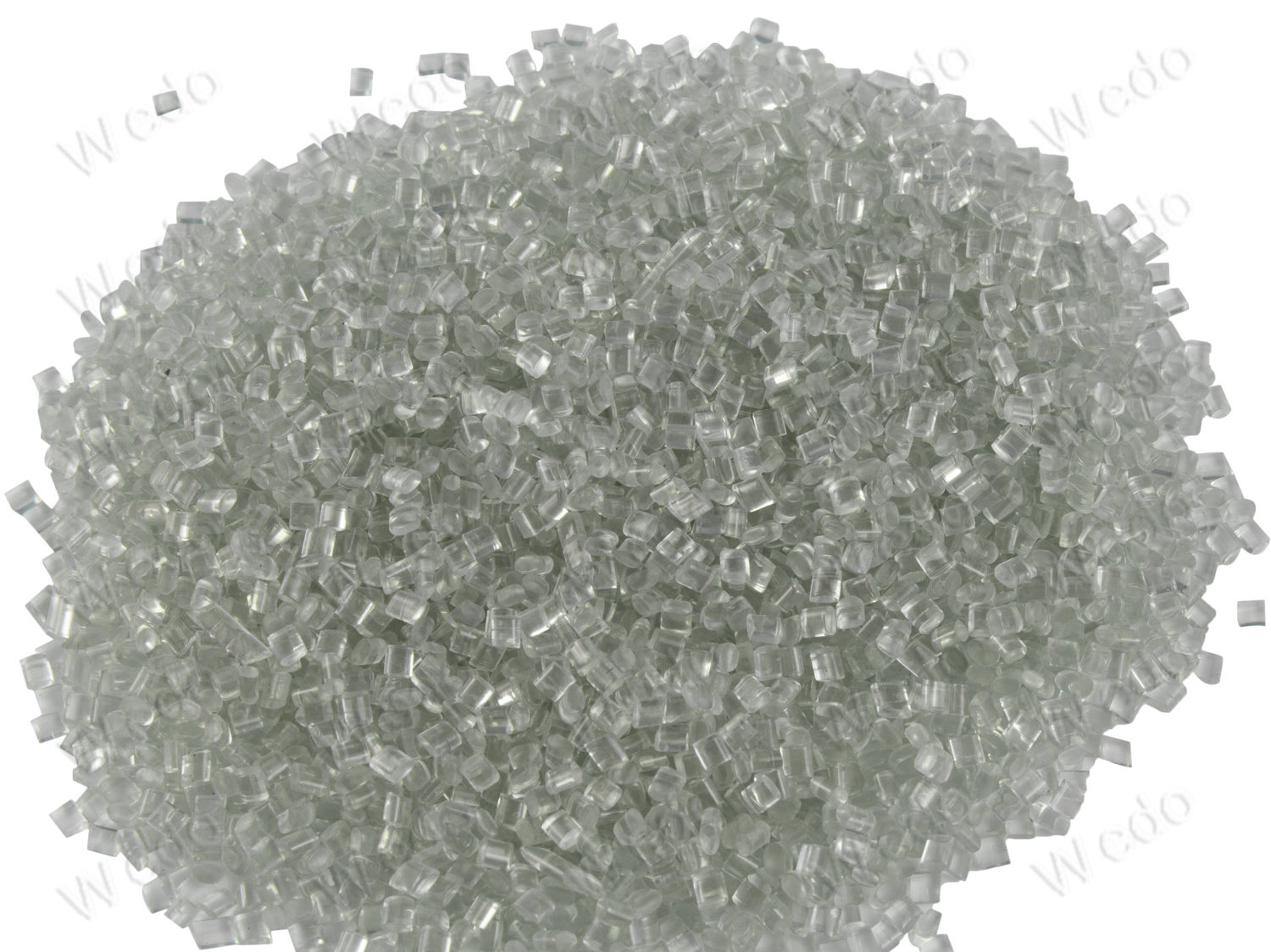

Po spracovaní techniky, ako je kŕmenie, kúrenie, roztopiť, chladenie, sušenie, rezanie atď., konečnými produktmi sú PET plastové pelety/granule, ktoré môžu slúžiť na výrobu nových PET plastových výrobkov.

Video of PET plastic flakes pelletizing recycling machine

Features of PET plastic flakes pelletizing recycling machine:

The screw is made of high tool steel 38 CrMoALA alebo W6Mo5Cr4V2. Špeciálna kombinácia skrutiek obdĺžniková hlaveň v štýle Euro, spätný chladiaci kanál optimalizovaný a usporiadaný, čím sa teplotný rozdiel v oblastiach D zmenšuje. Spoločne rotujúci dvojzávitovkový extrudér s prevodovkou s vysokým krútiacim momentom. Vďaka prevodovke s vysokým krútiacim momentom, Špecifický krútiaci moment prevodovky je 10.3 N.m/cm3, Takže môžeme spracovať PET pri nižšej teplote & nižšia rýchlosť, ale vysoký výkon.

Inovovaný dizajn ohrievača utiahnutého štýlu zaisťuje vysokú účinnosť prenosu tepla a vysokú životnosť ohrievača.

Ako materiál je použitá kvalitná nitridová oceľ, odolný proti korózii alebo proti treniu so zodpovedajúcimi spracovanými špeciálne navrhnutými dvoma sadami vákua. Vákuový systém sa používa na odstránenie vlhkosti & prchavé látky z PET. Je zostavený s vákuovými čerpadlami & zberná nádrž. S PLC a HMI ovládaním pre blokovanie, you will get the vacuum level less than 0.3Kpa. It is very close to the ultimate vacuum. You will get PET with IV drop less than 5%, it is about 0.05dl/g.

The selected material of drive components is dainty, including super intention alloy, cementiteing steel, cementiting and grinding.

Nový systém podvodného peletovacieho stroja: Vlákno prúdi do peletizéra, aj vlákno sa pretrhne pri výmene filtra, po naštartovaní nebude žiadny odpad.

Môžeme kontrolovať teplotu finálnych peliet. Môžeme zahriať, ak chcete kryštalizovať finálnu peletu. Ušetrí energiu na ohrev peliet.

Photos of PET plastic flakes pelletizing recycling machine

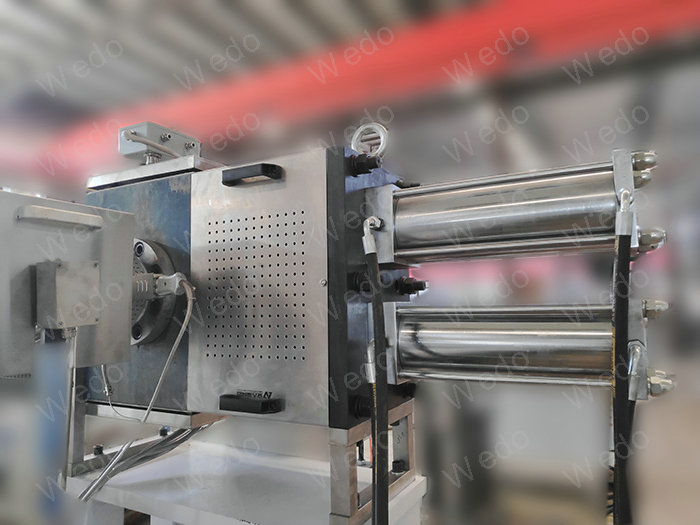

Main extruder, parrallel twin exturder of PET plastic flakes pelletizing recycling machine

Roots vacuum pump of PET plastic flakes pelletizing recycling machine

Hydraulic screen changer of PET plastic flakes pelletizing recycling machine

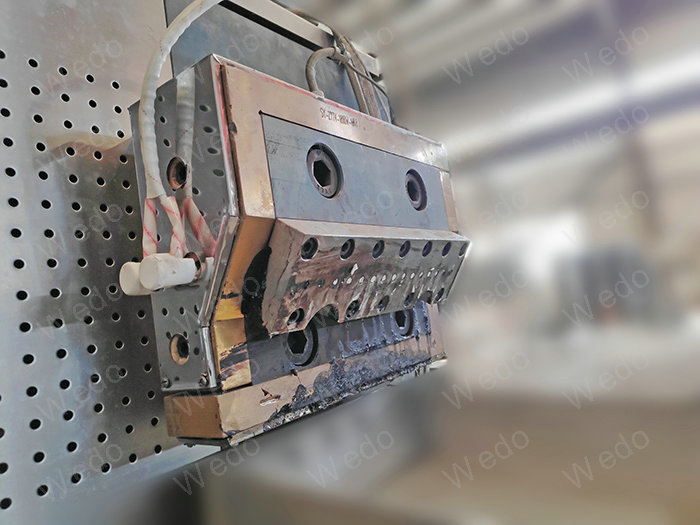

Die head of PET plastic flakes pelletizing recycling machine

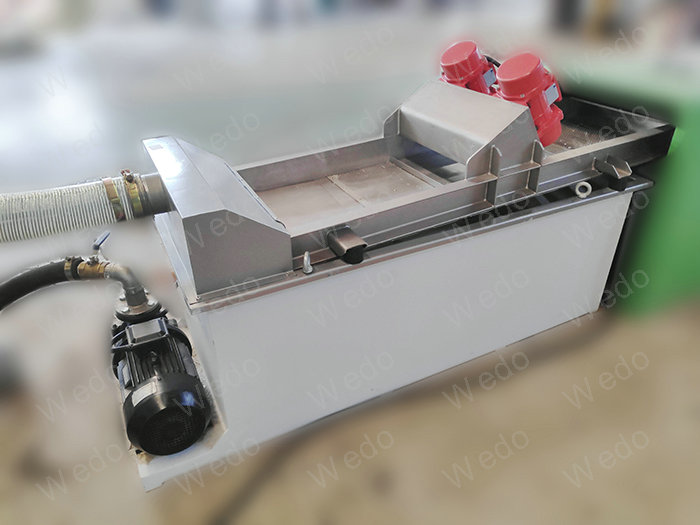

With water cutting, Pelletizer cutter of PET plastic flakes pelletizing recycling machine

Vibrationg machine of PET plastic flakes pelletizing recycling machine

PET pellets get from PET plastic flakes pelletizing recycling machine

Working Flow of PET plastic flakes pelletizing recycling machine:

Feeder → Efficient Extruder → Non-Stop Hydraulic Screen Filter Changer → Water Flow Cooling → Under Waster Cutting → Vibrating → Blower → Storage Hopper → Electric Control Panel

Main parts fuction in PET plastic flakes pelletizing recycling machine

- Screw feeder: the first step of the pelletizing recycling machine, PET plastic flakes/scraps conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

- Extruder: to plasticization and degassing, a specialized single screw extruder applied to melt the pre-compacted material. The plastic scraps will well melted, plasticized in the first stage extruder, and the plastic will be extrude by the second stage extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

- Non-stop hydraulic screen filter changer: double stage filtering, fore filtering in the first extruder, and fine filtering in the second extruder, to reduce the frequency of filtering sieves changing. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

- Water flow cooling: made of 304 nehrdzavejúca oceľ, 3 meters length that with flowing water, too cooling the melted PET strand.

- Cutting pelletizing: Water proof design, that can cutting the PET strand in water directly, this can save more waste. Supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

Parameters of PET plastic flakes pelletizing recycling machine:

| CAPACITY (kg/h) |

POWER CONSUMPTION (kw) |

WATER CONSUMPTION | LABOUR | HUMIDITY CONTENT |

| 100-150 | 150 | Keep water cool | 1-2 | <2% |

| 250-300 | 200 | Keep water cool | 1-2 | <2% |

| 350-400 | 280 | Keep water cool | 1-2 | <2% |

| 450-500 | 360 | Keep water cool | 1-2 | <2% |

Advantage of PET plastic flakes pelletizing recycling machine:

Very low labor request.

Automatic constant temperature control.

CE certification, ISO9001 certification, SGS certification

Stable running, higher output and lower energy consumption.

Configuration based on client requirement and material, and give reasonable suggest.