PE-rörtillverkningsmaskin, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

PE plastic pipe making machine adopts special HDPE/PP pipe efficient extruder. The screw made with a barrier and mixing head structure. The barrel uses a new slotted barrel, plastic and mixing effect is good, also has large and stable extrusion.

Vidoe of PE pipe making machine, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

Working flow of PE pipe making machine, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

Vacuum Loading → Raw Material Drying → Single Screw Extruder → Color Line Extruder → Mold → Vacuum Forming Tank → Spray Cooling Water Tank → Crawler Haul-Off → Planetary Cutter→ Stacker → Completed Product Inspection & Förpackning.

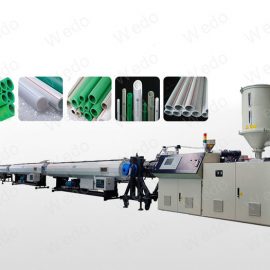

Photos of PE pipe making machine, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

extruder of PE pipe making machine, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

Vacuum calibration tank of PE pipe making machine, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

Haul-off machine of PE pipe making machine, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

Haul-off machine and cutting machine of PE pipe making machine, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

Specifications of PE pipe making machine, PE-rörproduktionsmaskin, PE-rörextruderingsmaskin

| Modell | Diameter(mm) | Extruders | Max.Output(Kg/h) | Total Power(KW) |

| PEG-110 | 20-63 | SJ65/33

SJ25/25 |

120-220 | 130 |

| PEG-160 | 75-160 | SJ65/33

SJ25/25 |

120-220 | 130 |

| PEG-250 | 110-250 | SJ75/33

SJ25/25 |

280-350 | 280 |

| PEG-450 | 160-450 | SJ90/33

SJ25/25 |

350-500 | 400 |

| PEG-630 | 315-630 | SJ120/33

SJ30/30 |

550-980 | 550 |

| PEG-800 | 400-800 | SJ150/33

SJ30/30 |

800-1400 | 750 |

| PEG-1600 | 800-1600 | SJ150/33

SJ30/30 |

800-1400 | 1200 |