PET-plastflingor pelletserande återvinningsmaskin

Beskrivning:

PET plastic flakes pelletizing recycling machine are applied to the waste materials, which needs high processing performance of melting, volatilization, filtering etc., mainly works for the job of PET scraps recycling and re-pelletizing.

PET plastic granulator machine with international advanced recycling technology and combined with the actual application condition. This PET plastic granulator machine is design specializes for recycling the recycled washed plastic PET plastic flakes/scraps, som t.ex. flingor/rester av Cola plastflaskor, renat vattenflaska flingor/skrot, PET-plåtflingor/skrot, PET dricksflaska flingor/skrot mm.

After processing techniques such as feeding, uppvärmning, smälta, kyl-, torkning, skärning etc., the final products are PET plastic pellets/granules that can be to produce new PET plastic products.

Video of PET plastic flakes pelletizing recycling machine

Features of PET plastic flakes pelletizing recycling machine:

The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2. Special screw combination Euro-style rectangle barrel, reflux refrigeration channel optimized and disposed, which makes temperature difference in D areas smaller. Co-rotating Twin Screw Extruder with High Torque Gearbox. Due to high torque gearbox, The specific torque of gearbox is 10.3 N.m/cm3, So we can process PET in lower temp & lower speed, but high output.

Innovated design of heater-tightened style insures high efficiency of heat transfer and high longevity of heater.

The material is used high quality nitride steel, corrosion proof or antifriction with corresponding processed special designed two sets of vacuum. The vacuum system is used for removing moisture & volatile matter from PET. It is assembled with vacuum pumps & collecting tank. With PLC and HMI control for interlock, you will get the vacuum level less than 0.3Kpa. It is very close to the ultimate vacuum. You will get PET with IV drop less than 5%, it is about 0.05dl/g.

The selected material of drive components is dainty, including super intention alloy, cementiteing steel, cementiting and grinding.

New Under Water Strand Pelletizing Machine system: The strand go into the pelletizer by the water flow, even the strand is break during changing the filter, there will no waste after starting.

We can control the temperature of the final pellets. We can make it hot, if you want to crystallize the final pellet. It will save the energy to heat up the pellets.

Photos of PET plastic flakes pelletizing recycling machine

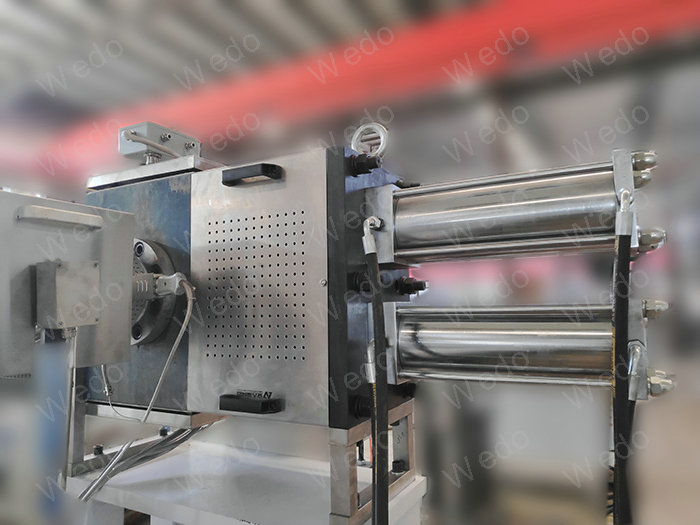

Main extruder, parrallel twin exturder of PET plastic flakes pelletizing recycling machine

Roots vacuum pump of PET plastic flakes pelletizing recycling machine

Hydraulic screen changer of PET plastic flakes pelletizing recycling machine

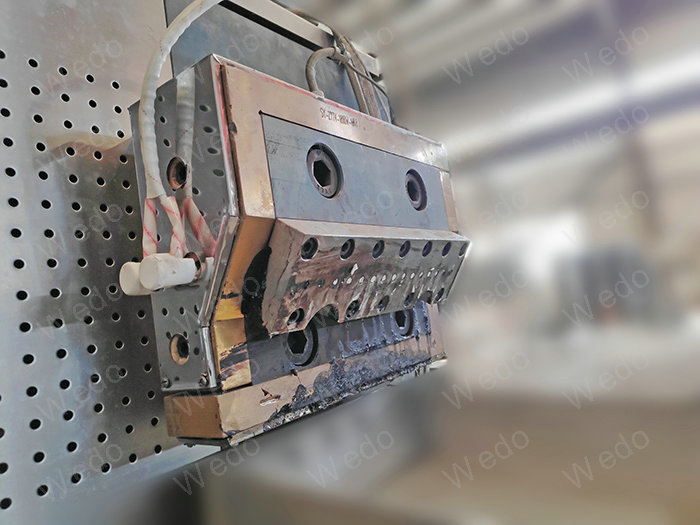

Die head of PET plastic flakes pelletizing recycling machine

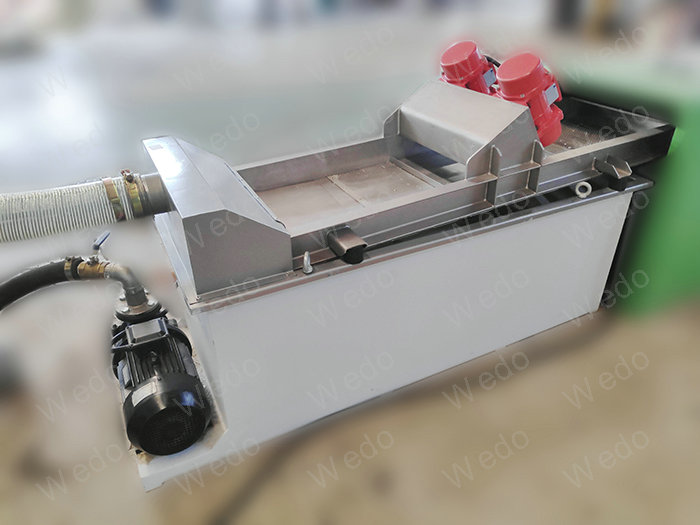

With water cutting, Pelletizer cutter of PET plastic flakes pelletizing recycling machine

Vibrationg machine of PET plastic flakes pelletizing recycling machine

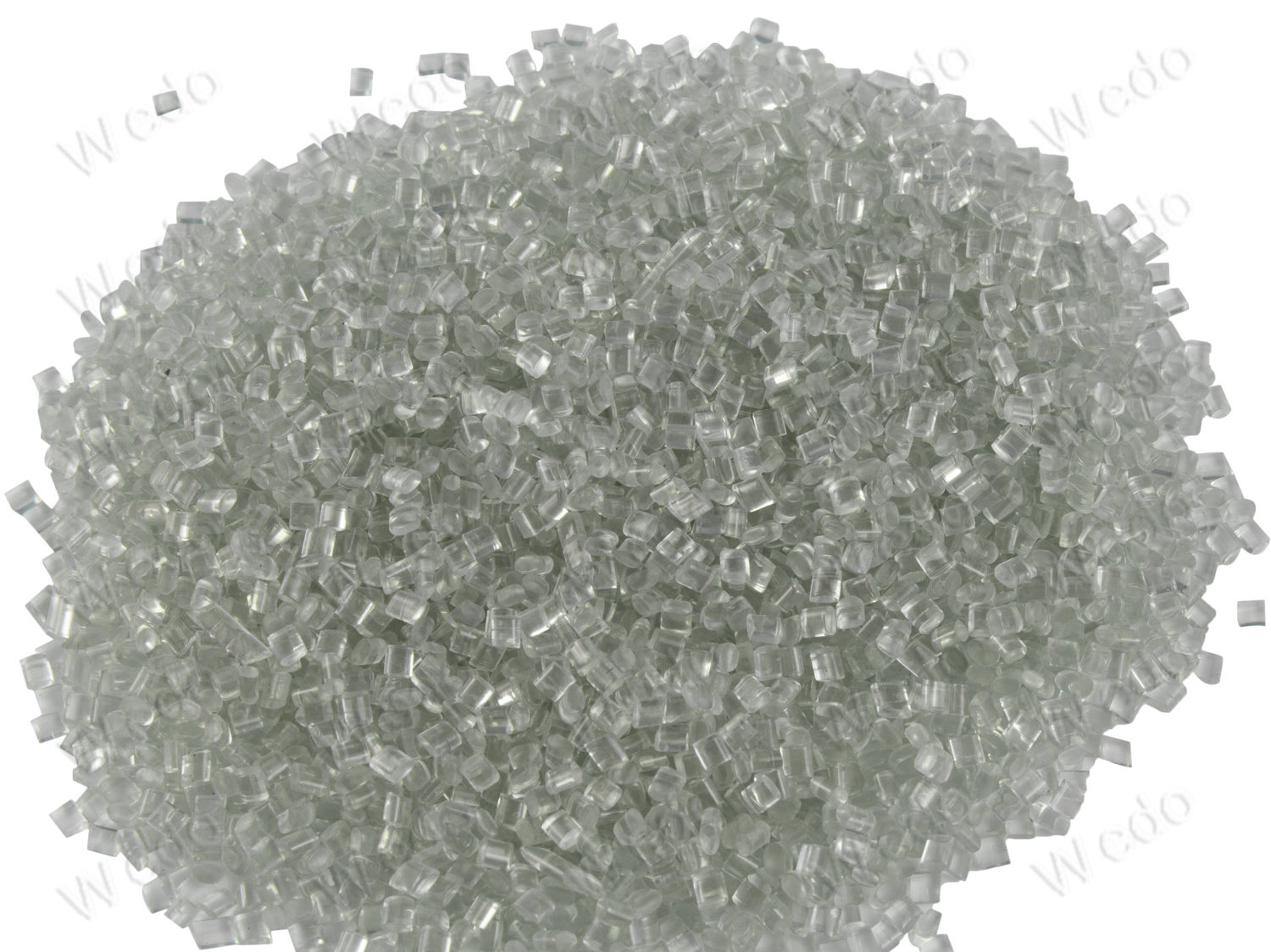

PET pellets get from PET plastic flakes pelletizing recycling machine

Working Flow of PET plastic flakes pelletizing recycling machine:

Feeder → Efficient Extruder → Non-Stop Hydraulic Screen Filter Changer → Water Flow Cooling → Under Waster Cutting → Vibrating → Blower → Storage Hopper → Electric Control Panel

Main parts fuction in PET plastic flakes pelletizing recycling machine

- Skruvmatare: det första steget i den pelleterande återvinningsmaskinen, PET plastic flakes/scraps conveyed into the hopper through screw, skruvanslutningssensorn för att detektera materialet i behållaren, när flingorna är fulla i behållaren, skruven kommer att stanna; och en gång tom, skruvmataren börjar fungera.

- Extruder: till plasticering och avgasning, en specialiserad enskruvsextruder som används för att smälta det förkomprimerade materialet. Plastrester kommer att smälta väl, plastad i det första stegets extruder, och plasten kommer att extruderas av andrastegsextrudern. Med dubbelzons vakuumavgasningssystem, flyktiga ämnen såsom lågmolekylära och fukt kommer att avlägsnas effektivitet, speciellt lämplig för tung tryckt film och material med viss vattenhalt.

- Non-stop hydraulisk silfilterväxlare: dubbelstegsfiltrering, förfiltrering i den första extrudern, och finfiltrering i den andra extrudern, för att minska frekvensen av filtreringssilar som ändras. Kraven på filtertekniken beror mycket på kvaliteten på insatsmaterialet samt den planerade användningen av granulat.

- Water flow cooling: gjord av 304 rostfritt stål, 3 meters length that with flowing water, too cooling the melted PET strand.

- Skärning pelletisering: Water proof design, that can cutting the PET strand in water directly, this can save more waste. Supplied with speed steel and hard alloy steel cutting blades for reliable performance. Kompakt struktur ger mindre underhåll.

Parameters of PET plastic flakes pelletizing recycling machine:

| KAPACITET (kg/h) |

ENERGIFÖRBRUKNING (kw) |

VATTEN KONSUMPTION | ARBETSKRAFT | FUKTIGHET |

| 100-150 | 150 | Håll vattnet svalt | 1-2 | <2 % |

| 250-300 | 200 | Håll vattnet svalt | 1-2 | <2 % |

| 350-400 | 280 | Håll vattnet svalt | 1-2 | <2 % |

| 450-500 | 360 | Håll vattnet svalt | 1-2 | <2 % |

Advantage of PET plastic flakes pelletizing recycling machine:

Mycket låg arbetskraftsförfrågan.

Automatisk konstant temperaturkontroll.

CE-certifiering, ISO9001 certifiering, SGS-certifiering

Stabil löpning, higher output and lower energy consumption.

Konfiguration baserad på kundens krav och material, och ge rimliga förslag.